The Technology Behind C6 Refined Detonated Nano-Diamond Ceramic Coating - A Lifetime of Protection

April 24, 2024

In the world of automotive detailing, ceramic coatings have become increasingly popular due to their ability to provide long-lasting protection and enhance the appearance of vehicles. However, not all ceramic coatings are created equal. The

C6 ceramic coating stands out from the rest, offering a unique blend of advanced materials and innovative technology that takes vehicle protection to the next level.

Silicon Nitride for Flexibility

One of the key components that sets the C6 coating apart is the use of silicon nitride, a flexible ceramic material known for its exceptional bonding properties. Unlike traditional ceramic coatings that can become brittle and prone to cracking or fracturing over time, silicon nitride maintains its integrity, ensuring long-lasting protection for your vehicle's paint.

The flexibility of silicon nitride allows it to expand and contract with the vehicle's surface, accommodating the natural movement caused by temperature changes and other environmental factors. This adaptability prevents the coating from becoming stressed and compromised, ultimately extending its lifespan and maintaining its protective qualities.

For detailers, the use of silicon nitride in the C6 coating means they can offer their clients a superior level of protection that won't deteriorate prematurely. Vehicle owners can have peace of mind knowing that their investment in a ceramic coating will provide lasting benefits, shielding their paint from the elements and preserving its pristine appearance.

Detonated Nano-Diamonds: Putting The C in C6

Another groundbreaking aspect of the C6 coating is the incorporation of refined detonated nano diamonds. These ultra-fine particles undergo a meticulous processing procedure to ensure consistent size and texture, enabling them to seamlessly blend with the other resins and ceramics in the coating mixture.

What are Detonated Nano Diamonds?

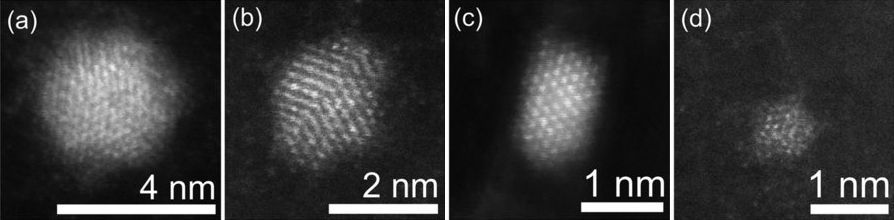

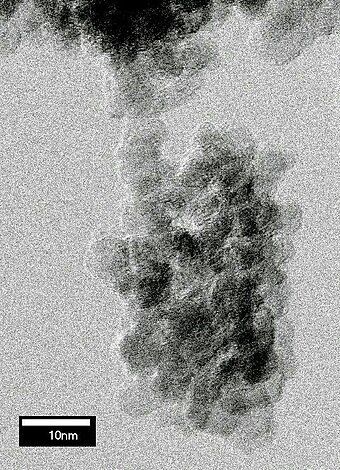

Detonated nano diamonds, also known as ultradispersed diamonds, are ultra-fine diamond particles produced through the detonation of oxygen-deficient explosives, such as a mixture of TNT and RDX, in a closed chamber. The resulting diamond particles have diameters of around 5 nanometers and possess unique properties that make them valuable in various applications, including advanced ceramic coatings like the C6.

How Detonated Nano Diamonds Work in C6 Ceramic Coating:

After the initial synthesis, the detonated nano diamonds undergo a meticulous refining process. This involves high-temperature, high-pressure boiling in acid for an extended period, which removes impurities such as metal contamination from the detonation chamber and non-diamond carbon. The result is a pure, consistently sized, and highly refined nano diamond product that is ready to be integrated into the C6 ceramic coating mixture.

The refined detonated nano diamonds have a uniform size distribution, which allows them to blend seamlessly with the other components of the C6 coating, such as the flexible silicon nitride ceramic and specialized resins. This homogeneous integration is crucial for the coating's overall performance and durability, ensuring that the nano diamonds are evenly distributed throughout the mixture.

When the C6 ceramic coating is applied to a vehicle's paint, the refined detonated nano diamonds form a dense, compact layer that provides exceptional resistance to wear. The hardness and durability of these nano-sized diamond particles create a barrier that shields the from the abuse caused by exposure to the environment. The uniform distribution of the nano diamonds ensures consistent protection across the entire treated surface, preventing uneven wear or degradation of the coating over time.

In addition to their protective qualities, the refined detonated nano diamonds contribute to the enhanced gloss and shine of the C6 coating. The nano-scale size of these particles allows them to reflect light in a way that intensifies the depth and clarity of the vehicle's paint, resulting in a stunning, mirror-like finish. The incorporation of these diamonds elevates the aesthetic appeal of the coated vehicle, making it stand out from the crowd.

The integration of refined detonated nano diamonds into the C6 ceramic coating plays a vital role in its long-lasting durability. These diamond particles are incredibly stable and resistant to wear, ensuring that the coating maintains its protective and aesthetic properties for an extended period. By incorporating these nano diamonds, the C6 coating offers vehicle owners a reliable, long-term solution for protecting their vehicle's paint and preserving its showroom-quality appearance.

In summary, the refined detonated nano diamonds used in the C6 ceramic coating are a key component that sets it apart from other coatings on the market. These ultra-fine diamond particles, meticulously refined and seamlessly integrated into the coating mixture, provide unparalleled protection, enhanced gloss, and long-lasting durability for vehicle paint. By harnessing the power of these nano diamonds, the C6 coating offers detailers and vehicle owners a superior solution for maintaining the beauty and integrity of their vehicles' exterior. Understanding the role of detonated nano diamonds in the C6 ceramic coating helps illustrate the advanced technology and attention to detail that goes into creating this exceptional product.

Better Bonding and Faster Curing

One of the most impressive features of the C6 coating is its ability to penetrate and bond with the vehicle's paint at a deeper level. When applied, the coating mixture swells the paint slightly, allowing it to infiltrate the surface and establish a strong internal bond.

This enhanced bonding mechanism is the secret behind the C6 coating's rapid curing time. Once applied, the outer layer of the coating cures quickly, forming a protective shield that allows the vehicle to be driven just one hour after application, even in rainy conditions. This fast-acting property is a significant advantage for detailers, as it enables them to complete projects more efficiently and reduces the risk of contamination during the curing process.

For vehicle owners, the swift curing time of the C6 coating means minimal downtime and the ability to enjoy their newly protected vehicle almost immediately. The strong internal bond ensures that the coating remains firmly adhered to the paint, providing long-term protection against the elements and environmental pollutants.

Easier Maintenance with Persistent Protection

Maintaining a vehicle treated with the C6 ceramic coating is a breeze compared to other protective solutions. The coating's durable and hydrophobic properties make it resistant to dirt, grime, and water spots, allowing for easier cleaning and maintenance.

To keep the coating in optimal condition, vehicle owners simply need to wash their car when it becomes dirty and occasionally perform decontamination as needed. Unlike some other coatings that require annual reapplication, the C6 coating offers enduring protection without the need for frequent touch-ups or refreshes.

For detailers, the simplified maintenance of the C6 coating translates to happier clients who can enjoy their vehicle's pristine appearance with minimal effort. The coating's long-lasting protection also means that detailers can focus on attracting new clients rather than constantly servicing existing ones.

Exceptional Gloss, Slickness and Performance

With over two decades of experience in the ceramic coating industry, the creator of the C6 coating has witnessed firsthand the evolution of protective technologies. What sets the C6 coating apart is its unparalleled combination of glossiness, slickness, and durability.

The advanced formulation of the C6 coating enhances the depth and clarity of the vehicle's paint, creating a stunning, mirror-like finish that turns heads and showcases the true beauty of the car's color. The slick surface of the coating reduces friction, making it easier to clean and maintain while also providing a satisfying tactile experience for vehicle owners.

But perhaps the most impressive aspect of the C6 coating is its exceptional durability. By allowing the bonding layer to fully cure and cross-link for seven days before any washing, the coating achieves maximum adhesion and long-term resilience. This extended curing period ensures that the coating becomes an integral part of the vehicle's paint, offering protection that far surpasses traditional waxes and sealants.

For detailers, the unrivaled performance of the C6 coating allows them to deliver results that exceed client expectations. The stunning gloss, slick feel, and long-lasting protection set a new standard in the industry, giving detailers a competitive edge and the ability to build a loyal customer base.

The C6 ceramic coating represents a significant advancement in automotive protection technology. With its innovative use of silicon nitride, refined detonated nano diamonds, enhanced bonding capabilities, rapid curing time, simplified maintenance, and unmatched gloss, slickness, and durability, the C6 coating offers detailers and vehicle owners a superior solution for preserving the beauty and integrity of their vehicles.

For detailers, incorporating the C6 coating into their services allows them to differentiate themselves in a competitive market, deliver exceptional results, and build a reputation for quality and expertise. Vehicle owners can enjoy the peace of mind that comes with investing in a high-performance ceramic coating that provides long-lasting protection and maintains the showroom-quality appearance of their prized possession.

In a world where vehicles are exposed to harsh environmental conditions, damaging pollutants, and the rigors of daily use, the C6 ceramic coating emerges as a true game-changer. Its advanced technology and unparalleled performance set a new standard for automotive protection, making it the ultimate choice for those who demand the best for their vehicles.